Where is each technology along its commercial path? What has been the most challenging aspect?

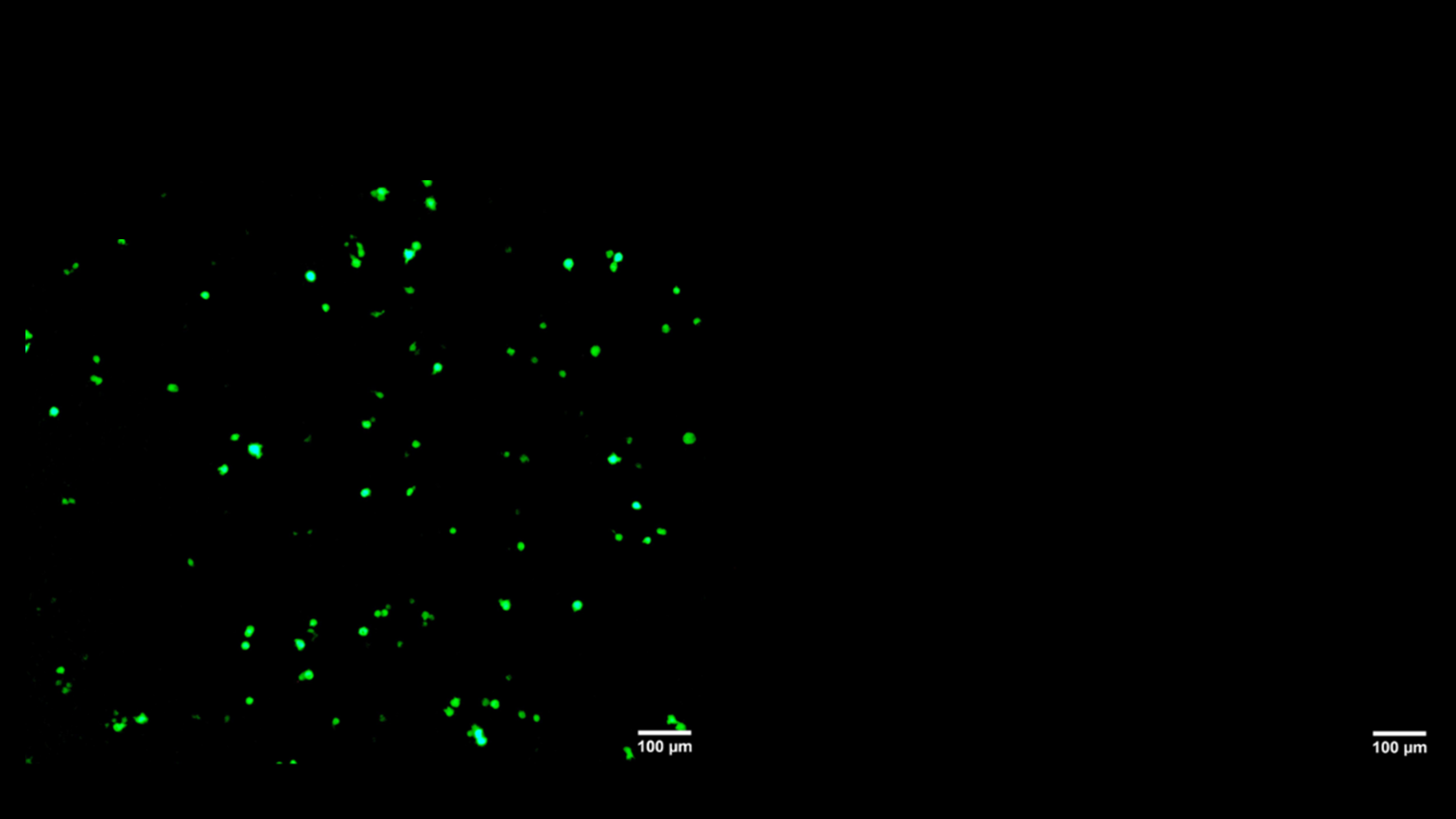

Lauren: AeroVeil is moving toward FDA approval. Our first meeting with the FDA was a huge milestone. The most challenging aspect has been navigating the regulatory pathway while refining the technology. Adhesion prevention is complex, requiring rigorous studies to establish product safety and performance. But hearing excitement from others in the field has been reassuring about the importance of this work.

Kelley: Proteus is in advanced development and testing. We have prototypes and are looking for opportunities to collect data in training environments to further develop our algorithms. The challenge is collecting enough data in representative environments to develop tailored performance and risk indicators for our warfighters. We are also balancing competing requirements such as size, power, durability, accuracy, and cost. Every improvement in one area creates challenges elsewhere. Finding the right trade-offs for real field use requires constant iteration. Working with DOD customers ensures we’re building something that truly meets their needs.

How do the Materials and Biotech divisions collaborate?

Lauren: The collaboration is seamless. Projects often require both materials expertise and understanding of biomechanics or physiology. We don’t work in silos. We approach challenges as a team and figure out together what combination of perspectives, areas of expertise, and solutions will work best.

Kelley: What makes it work is that we’re often doing things that haven’t been done before. It’s not ‘I know the answer, go execute this task.’ It’s ‘let’s figure this out together’ whether you’re a senior engineer or a student intern. The meaningful innovations happen at the intersections where materials science meets electronics or biomechanics meets sensor design.

What keeps you coming to work every day?

Kelley: Working with the team to solve big challenges and seeing innovative solutions develop. We all start with a vision, but it evolves as the team figures out the best direction. I’m constantly amazed at what we accomplish and seeing the impact when customers use our devices in ways that change how their world works.

Lauren: Working with brilliant minds and being challenged daily. I believe in the potential of our projects to make real impact. There are no two identical roles here. Everyone has unique contributions and takes real ownership of the work they’re doing every day.

Looking back on your careers at Luna Labs, what are some of your proudest moments?

Lauren: Our first FDA meeting stands out. Going to the table with them after years of work was a major milestone. It’s been a long development road, but the words of encouragement and excitement that we hear from clinicians and from others in the adhesion prevention space – that reassurance means a lot.

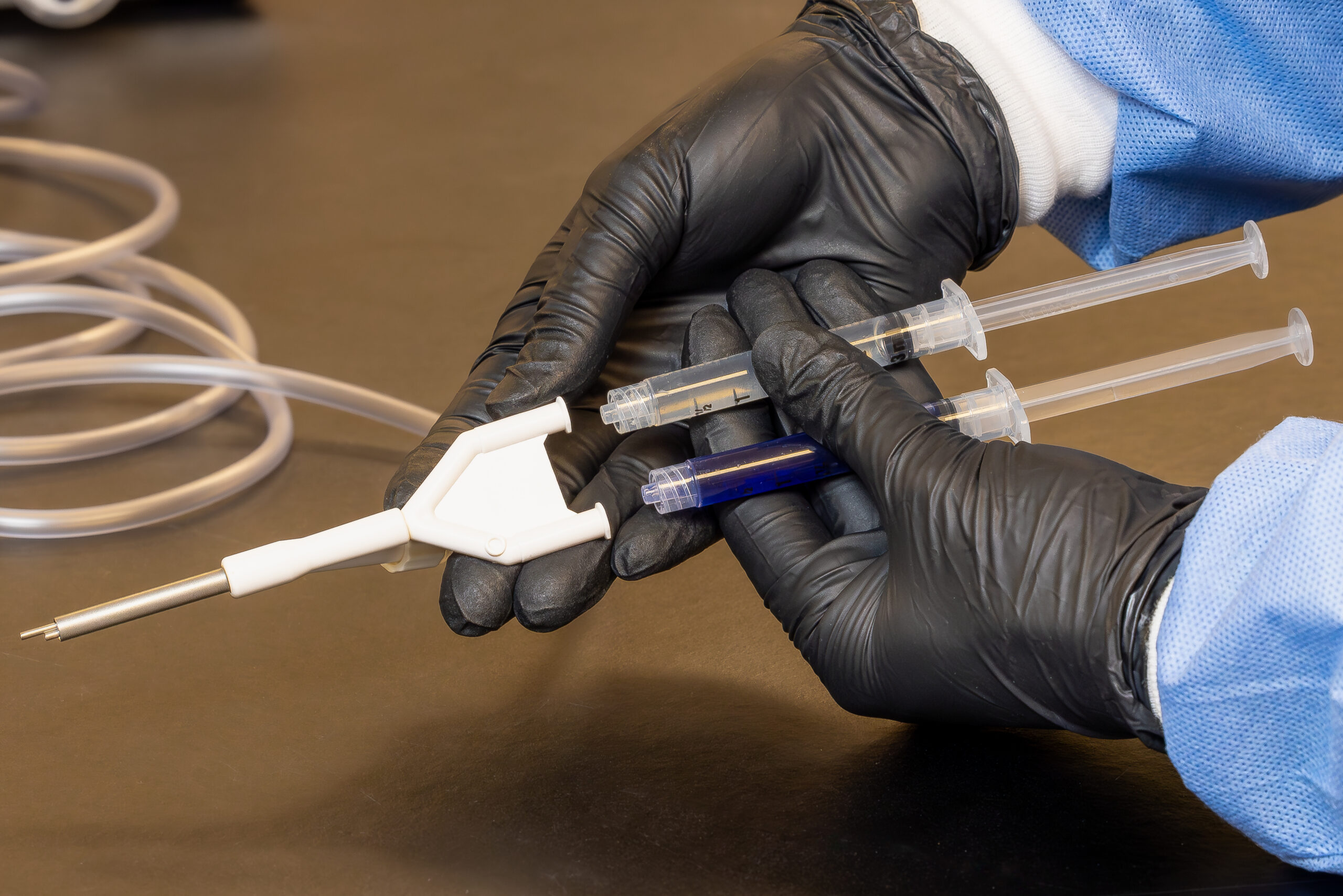

Kelley: The first sale of our Dislotech Joint Reduction Trainer was exciting. We built something everyone said had no market, then had someone want to pay for it during Phase II SBIR. Now our medical simulation training products have been acquired by Integrated Medcraft. Seeing students practice on it before doing real procedures and knowing we were changing outcomes – that’s powerful.

And 3WAVES, our virtual motion system for flight simulations. Seeing the entire team contribute to something that could change the effectiveness of flight simulations. From shoulder simulation to flight simulation to warfighter protection, the breadth shows we can tackle complex problems across very different domains and do it well.