Drake Goolsby, Luna Labs’ inaugural Chief Commercialization Officer, was recently interviewed by the Virginia Economic Development Partnership (VEDP) for its Virginia Economic Review podcast. We captured the high points below. Listen to the full podcast here.

Can you give us a high-level overview of Luna Labs’s mission, vision, and activities? What problems is the company attempting to solve?

We are a product development company that primarily serves the defense and biotech markets. We started as a division of a larger company in 2001 but we recently spun out through a private equity acquisition which opened up some exciting growth opportunities for us. Our strength is taking products from initial concept through development and early-stage growth. At that point, we look for external partners who help take these products to the next level for additional growth opportunities.

We bridge the gap between small-business agility and large-business capabilities. I’ve worked for very large companies, really great companies, but I’ve seen how R&D can get stifled. At Luna Labs, we’re a company that can both think broadly and move quickly.

Our contract research division, funded through government Small Business Innovation Research (SBIR) funds, gives us a foundation to be able to think broadly and tackle diverse challenges for our government clients. It’s about spotting high-potential opportunities across different sectors, where a product fit matches up with a market pull opportunity – that’s when we can accelerate growth. So we’re excited for our path ahead.

Could you discuss Luna Labs’ work with materials research? What are the company’s priorities? What has the company done that you’re excited about the most?

We have three divisions — materials, biotech, and systems — but what’s fascinating is that materials science is the thread that connects all three.

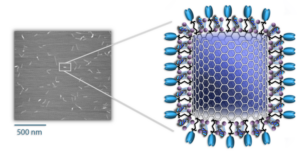

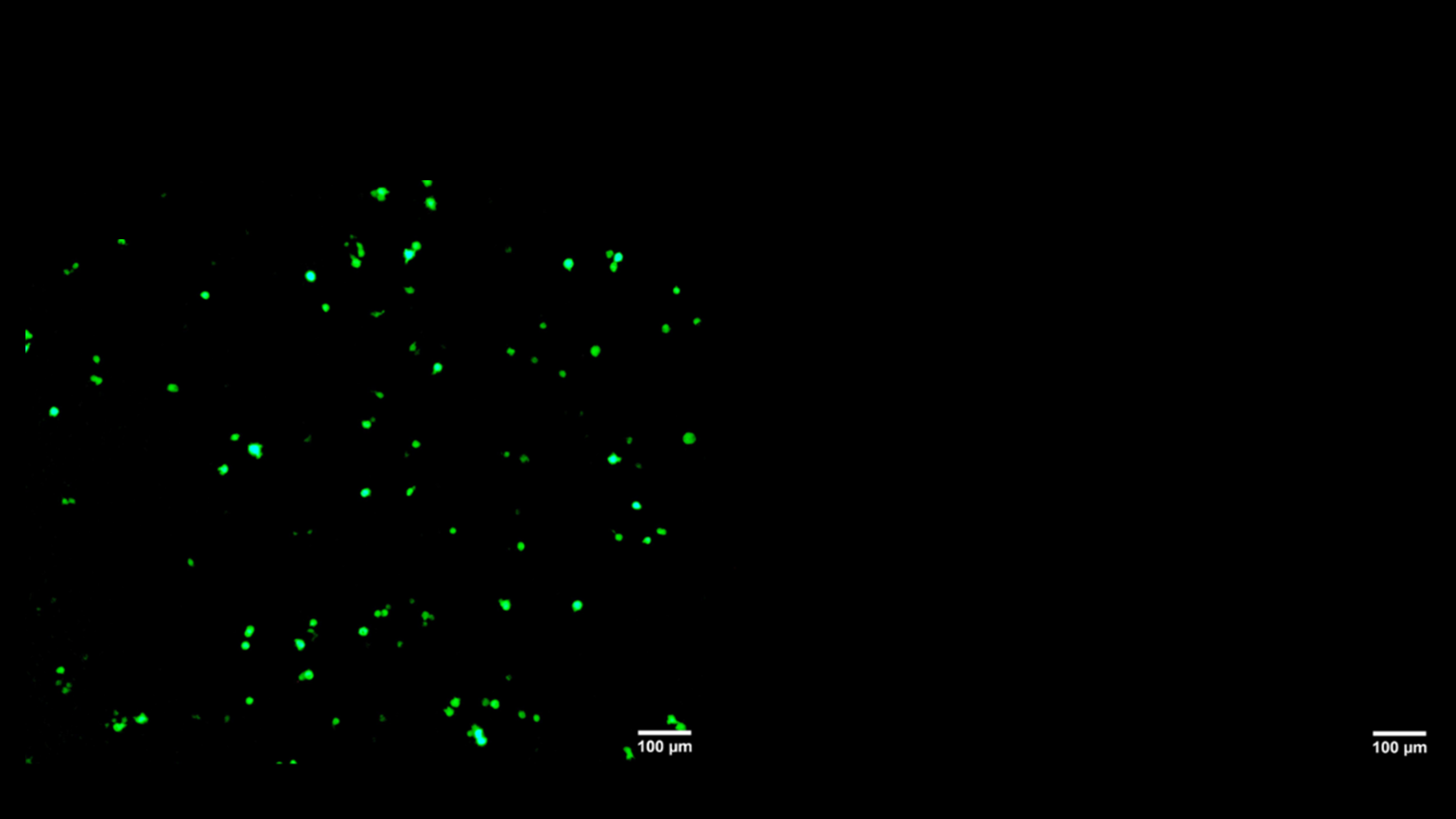

For example, our biotech group is developing NanoVac, a novel drug delivery platform for infectious diseases and vaccine development. It’s actually mimicking nature – what’s known as biomimicry – using carbon nanotubes. Leveraging that into drug delivery is a novel thought, and a great example of using our materials expertise and applying it in an unexpected way to solve challenges in healthcare.

An electron microscope is required to see the NanoVac delivery vehicle, with each rod 100-200 nm long. In the schematic, the loading of nucleic acids and proteins on the surface of the vehicle is illustrated.

Our medical simulation business created TrueClot, a product line with simulated blood for bleeding control training. It’s a really cool product that feels and behaves like human blood, and it even forms blood clots. First responders all over the world are using our wound trainers to learn how to administer bleeding control for bullet wounds and other serious trauma injuries

The TrueClot® Inguinal Packing Trainer is a wearable training aid that simulates a junctional hemorrhage and teaches advanced wound packing skills..

Then there’s our work in corrosion management under our systems group. Traditional corrosion testing – think about planes and ships and wind turbines – typically takes years of waiting for results when you’re testing new protective coatings or materials. We’ve developed Acuity Corrosion Technology, a system that cuts the timeline down to under six months. While this technology is rooted in electrical engineering, it’s really about leveraging materials science to weave the connection about how different materials interact with harsh environments.

The Acuity LS provides continuous, real-time onboard monitoring of a full suite of environmental and corrosivity parameters.

These products may seem worlds apart – from drug delivery to bleeding control training to corrosion management. But that’s what makes our capabilities unique. With the thread of materials science running through everything we do, we spot opportunities and make connections others might miss.

Describe some of the strengths that you see in your materials, R&D, and the commercialization side?

One of our greatest strengths is how well our team collaborates across divisions The majority of our employees are advanced-degree engineers and scientists across various disciplines. What’s even more special than tapping into all that talent is how well they collaborate. We’re cultivating an environment where a materials scientist might be brainstorming with a biologist and an electrical engineer. This flexibility – this teamwork – allows us to tackle really niche, complex challenges that come up with our contract work. It often leads us to solutions we might never have thought of if everyone just stayed in their own labs.

We’re also strategic in how we bring these solutions to market. Rather than trying to be the global leader in a market category, we focus on creating a value-add for commercial partners. We look for companies that have market share and are open to external innovation – companies that need the kind of targeted solutions we excel at developing. This flexible business model is a real differentiator for us. We can solve technical issues through collaborative problem-solving and we can be creative getting our solutions to markets where they can have impact. That is a real strength for us.

It sounds like Luna Labs sees itself as the innovation inside the innovation. Does that sound right?

We think commercialization is about combining two critical elements: relentless determination with a whole lot of creativity. It’s an orchestrated process between product development and market timing. We gather the market intel and get to know our customer base and their needs. Sometimes we recognize the market or the technology isn’t quite ready so we incubate the project until the timing is right. Other times we hit the accelerator to move fast to capitalize on a product’s potential. Understanding our product development potential and matching that up with market timing is the art of commercialization.

There’s an art to knowing when to push forward aggressively and when to nurture development more slowly.

Drake Goolsby

Do many of your team members come from the University of Virginia? Is being that close to the university a benefit to you? How do you interact with or work with other Virginia universities?

We have facilities in both Charlottesville and Blacksburg with strong ties to Virginia Tech and the University of Virginia. These are two incredible schools with really great engineering programs, as well as a focus on biotechnology. It’s a wonderful recruitment opportunity for us to bring in young, bright talent as well as a pipeline for strong research collaborations. We actually have collaborative research partnerships with universities and companies around the world, including the research institutes in Virginia.

You mentioned that you have a close interface with the federal government, and you’re using some SBIR funds to stand up a part of the company. Can you tell me a little bit more about how Luna Labs interfaces with the federal government?

SBIR is a program that funds research and development by small businesses. It’s one of the largest public-private partnerships in the country. It’s a competitive process that connects small businesses like ours – less than 500 employees – with federal R&D needs,

We use this program strategically for delivering solutions that match up to government needs, especially those of the U.S. Department of Defense. For example, our corrosion management system and some of our protective coatings were developed for aerospace applications. We have another coating sealant that was developed as a transparent armor to reduce delamination of windows for ground vehicles in harsh conditions. This is where our approach to innovation really shines. We look for adjacent opportunities to further adapt and develop these technologies, potentially to meet different market needs. Our cross-disciplinary approach helps us make these connections across industries and understand how to modify solutions for different applications.

What does innovation mean at a company like Luna Labs?

For us, innovation is about challenging assumptions and seeing possibilities where others might see dead ends. Why hasn’t the problem been solved? What’s different today that might make it possible now? We never let yesterday’s constraints limit today’s thinking. When we approach a challenge, we think of it as a puzzle. You would never just pick a random piece and try to place it correctly in the middle. You would create the outer frame then work into the middle of the puzzle. That’s how we approach innovation and commercialization. We start with where we are today mapping out next steps. But we also work backward from our end goal. When these two paths meet, we have a framework for moving forward with creative possibilities and practical strategic planning.

There is something special about the entrepreneurial community in Charlottesville, specifically around biotechnology and life sciences. You’re new to the Charlottesville area – have you found it to be a supportive community?

Charlottesville has a strong, thriving life science community that our biotech group especially has tapped into. But it’s not just biotech. There is a growing ecosystem focused on science and technology solutions, including for the defense industry. Luna Labs is well-positioned to both support these networks and grow our partnerships with other Virginia-based companies.

Drake Goolsby joined Luna Labs in May 2024 as its inaugural Chief Commercialization Officer. Drake came to us from Battelle where he was VP for Commercial Strategy and Business Development, leading Battelle’s global commercial business. He also held positions as Director of Operational Transformation at Texas Health Resources, Industry Manager for Contract Manufacturing at PepsiCo, and Project Engineer at Jacobs.

Luna Labs is interested in partnerships and collaborative research and development. Reach out and let us know about your interests.

More Articles

-

Innovation at the Intersections: How Luna Labs Creates Breakthrough Solutions for Patients and Warfighters

What makes Luna Labs different in biomedical innovation? Biotech Division managers, Lauren Costella and Kelley Virgilio, reveal the company's unique approach to tackling complex biotech challenges.

Categories

Tags

-

A More Effective Way to Deliver Therapeutics Across the Body’s Natural Barriers

NanoVac is a delivery platform that mimics virus structure to navigate the body's defenses and deliver drugs more effectively.

Categories

Tags

-

Excitement Builds for 2026: Latest News from Luna Labs’ Acuity Corrosion Team

Reflecting on Acuity 2025 highlights and preparing for another meaningful year of connection and innovation.

Categories