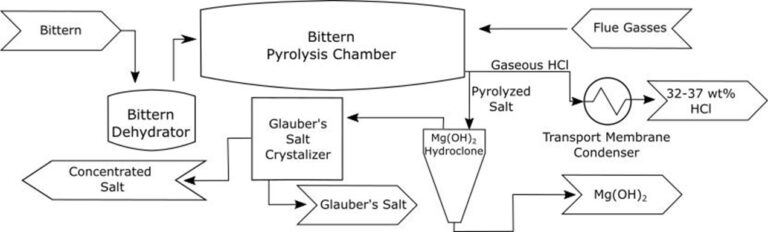

The process of solar evaporation of seawater for salt production generates a bittern byproduct, which is rich in sodium, potassium, magnesium, chloride, and sulfate. Previous attempts to extract valuable minerals from bitterns have been economically unsuccessful. However, Luna Labs’ innovative Hydrochloric Acid (HCl) Extraction technology allows for the profitable conversion of salt and salt mixtures into value-added chemicals crucial to the domestic economy. The Bittern Valorization process by Luna Labs increases the efficiency of mineral production by pyrolyzing the magnesium chloride-rich mixture to produce HCl. Luna’s method is fundamentally unique because it avoids the use of expensive chemical consumables (e.g., NaOH, CaCO3) and instead focuses on extracting HCl with minimal heating costs.

After drying the bittern until magnesium reaches the dihydrate state, the production of Mg(OH)2 enables efficient follow-on separations to produce Glauber’s Salt (Na2SO4), potassium chloride (KCl), and additional sodium chloride (NaCl). North America currently produces roughly 13 million tons of bittern, most of which appears to be available for consumption outside the Great Salt Lake area. The Bittern Valorization process maximizes mineral resources by reducing the solar evaporation byproduct footprint by over 90% and could increase a salt production facility’s nameplate capacity by more than 20%, while also decreasing the process carbon footprint.

An engineering review and an AACE level 4 cost estimate of the overall process by Trimeric Corporation have concluded that there is a favorable 10-year internal rate of return (>40%). The major capital expenditures are dryers for salt preparation and HCl extraction steps. The purchased equipment cost is $77M, and the total installed cost is $272M. A projected design basis of 1 million tons of bittern per year was used to determine equipment sizing and capital expenses. A process net revenue of $118/ton, primarily driven by $150/ton HCl product, results in an annual net revenue of $118M.