Revolutionary Chromate-free Corrosion Control Coating

Galvanic corrosion on aircraft around mechanical fasteners represents a significant portion of total maintenance costs and contributes toward reduced operational readiness.

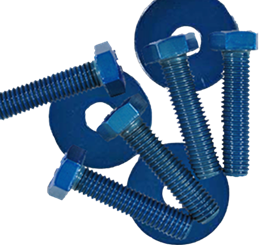

Historical approaches to controlling galvanic corrosion involve protecting the anode (e.g. usually the aluminum airframe), but minimal efforts have been made to limit the galvanic contribution at the cathode.

What if we could control the available cathodic current to limit corrosion?

There is a need to improve the galvanic corrosion control tool set across these platforms, and technologies that control cathodic current density are a new approach.

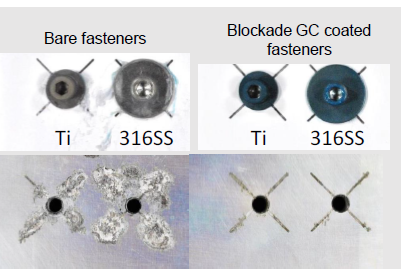

Blockade GC coated fasteners.

Blockade GC™

A hybrid sol-gel coating to impede the development of corrosion and enhance durability and overall performance.

Ideal for aerospace and marine structures.

Fasteners coated with Blockade GC installed in an HH-60G aircraft.

A cadmium-plated bolt coated with Blockade GC.

Luna Labs has developed a revolutionary product called Blockade GC, a cutting-edge chromate-free corrosion control coating designed for aircraft fasteners and rivets but applicable to corrosion mitigation challenges across multiple industries.

This remarkable coating serves as a durable and thin barrier, providing exceptional galvanic corrosion mitigation around fasteners, bushings, and other dissimilar metallic interfaces.

What sets Blockade GC apart is its ability to block the electrical current that triggers corrosion, effectively addressing the root cause of the problem. By preventing galvanic coupling between components, this innovative coating not only hinders the development of corrosion but also significantly enhances durability and overall performance. It is both an eco-friendly and cost-effective solution that can be easily applied at the factory or by a skilled applicator, eliminating the need for additional steps during installation.

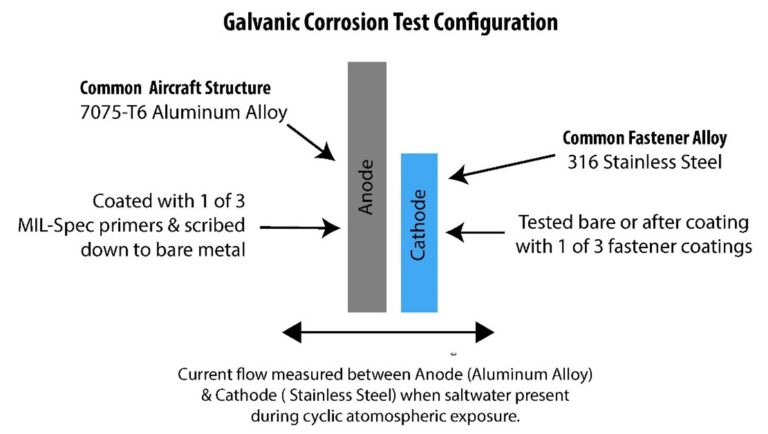

Galvanic corrosion protection performance of different common fastener finishes compared to Blockade GC coated fasteners. The Blockade GC coating resulted in substantial reduction in aluminum galvanic corrosion damage (i.e. charge), and in some cases a reduction by as much as > 80%. Blockade GC provides consistent and predictable corrosion control, with performance greater than or equal to existing materials.

Total galvanic corrosion in Coulombs shows as a function of sensor panel coatings. Uncoated, Blockade-coated, and COTS-coated 316 stainless steel sensor panels were mated to 7075 aluminum panels coated with 3 different primer systems. These panel assemblies underwent cyclic testing in an environmental chamber, with measured current between the panels used to calculate galvanic corrosion.

Aluminum panels with installed fasteners subjected to corrosion testing. Blockade GC coated fasteners resulted in less aluminum damage than bare titanium and 316 stainless steel fasteners.

Benefits

Sol-gel formulation offers economical solution.

Uses factory-ready parts.

Compatible with various hardware types.

No pre-treatment required.

Thin barrier coating (4-8 microns) ensures compatibility with existing hardware designs.

Opportunity

Our galvanic corrosion protective coating solution is available for licensing.

Our patent pending invention is available for license to companies with commercial interest.

Luna Labs is also interested in partnerships and collaborative research and development.