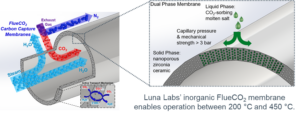

In the effort to achieve reduced carbon emissions globally, capturing carbon at the source (point capture) is a critical component to any viable strategy. The FlueCO2 technology, developed by Luna Labs, is designed for integration into natural gas combined cycle (NGCC) power plants to capture CO2 post-combustion by removing carbon from the flue gas. The FlueCO2 membrane works with an active transport mechanism that powers CO2 separation with low pressure steam and H2O’s concentration gradient. FlueCO2 offers superior separation performance capture with an unrivaled combination of CO2 permeability and selectivity of CO2 over nitrogen (N2).

In the effort to achieve reduced carbon emissions globally, capturing carbon at the source (point capture) is a critical component to any viable strategy. The FlueCO2 technology, developed by Luna Labs, is designed for integration into natural gas combined cycle (NGCC) power plants to capture CO2 post-combustion by removing carbon from the flue gas. The FlueCO2 membrane works with an active transport mechanism that powers CO2 separation with low pressure steam and H2O’s concentration gradient. FlueCO2 offers superior separation performance capture with an unrivaled combination of CO2 permeability and selectivity of CO2 over nitrogen (N2).

Using methodologies laid out in the National Energy Technology Laboratory (NETL) Cost and Performance Baseline for Fossil Energy Plants, Luna Labs modeled the performance of NGCC power plants with the FlueCO2 technology across different electricity pricing scenarios, carbon tax/credit structures, and regulatory structures. FlueCO2 NPV projections are greater than the B31A power plant in any future regulatory/tax scenario and outperforms the B31B power plant in all 14 scenarios.

Conventional Dual-Phase Membranes

- Molten carbonate liquid phase

- Solid oxide ion conduction required to maintain mass/charge balance and transport CO2 through liquid phase

- Requires high temperatures (>600 °C)

FlueCO2 Dual-Phase Membranes

- Molten hydroxide-carbonate liquid phase

- All mass transport through the liquid phase by coupling CO2 permeation with the partial pressure of water vapor

- Fast, low temperature operation (200 °C)

For more information:

- Contact: carbon.capture@lunalabs.us